As part of the Warrior platform, new six-sided combat boots have been introduced since last year.

image text translation

image text translation

But the traditional Trexta combat boots are expensive.

M Plus-gu Military Mutual Aid Association Delivered with Bentex material The Marine Corps is delivered with Trex.

An official from M+ who applied the Bentex material said, “The Bentex material meets the performance value of physical properties required by the military.

I heard that the 2017 prosecution investigation proved enough.

The military’s purchase request said there was no requirement for the weapons system’s ROC to maintain its physical properties to some extent after several washes.

The official said that the company’s six-sided combat boots were delivered last December.

“Since it was the first time to deliver six-sided combat boots, I didn’t think some of the leather would happen or crumble,” he explained.

He also said that at the request of the soldiers, he is currently replacing the problematic combat boots with new ones.

We are making efforts to improve the quality.”

image text translation

(1)Quality regulations Use domestic material endothelium instead of Gore-Tex

(2)Since October last year, the Military Mutual Aid Association and the Jeonbuk Dance Village have used the materials of Bentex, a Korean company, instead of Gore-Tex, which they decided to use as an endothelium material when signing a supply contract.

(3)If you use materials from Bentex, the price of materials per pair will be about 3,000 won cheaper.

(4)However, these companies posted documents to the agency based on relatively expensive Gore-Tex that they had to present to calculate the cost ahead of the contract for the supply of combat boots in September this year.

(5)According to Rep. Lee, this inflated total cost amounts to 2.7 billion won.

(6)The agency recognized in October that these companies changed their endothelium to domestic materials, not Gore-Tex, but did not recognize it as a fraudulent profit.

a two-line summary

These are Gore-Tex combat boots.

2 Gore-Tex not included

For your information, the ocean industry under M+M of the Military Mutual Aid Association

image text translation

(1)Our company is the only Korean manufacturer of combat boots.

(2)We’ve brought in leather finished products, and we’re working on the entire production process from the foundation to sewing. Although it should not be compared to other companies, I understand that Company K, Korea’s leading manufacturer, does not have the same facilities as ours and is highly dependent on outsourcing. “Our ocean industry is where we can produce 1.2 million pairs per year immediately after exhibition with a perfect process system.”

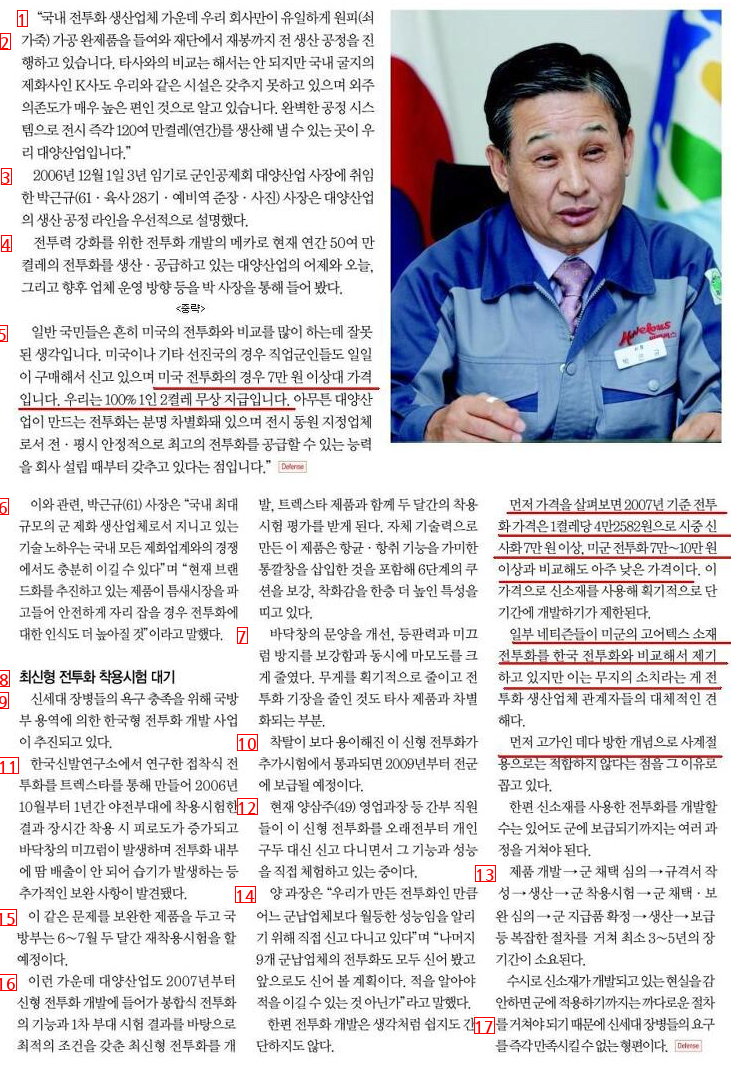

(3)Park Geun-gyu 61, the 28th Army Division, Reserve Brigadier General, and Photo President, who took office as president of the Daeyang Industry Association for a three-year term on December 1, 2006, explained the production process line of the Daeyang Industry first.

(4)As a mecca for developing combat shoes to strengthen combat capabilities, we heard yesterday, today, and the future direction of the company’s operation in the ocean industry, which currently produces and supplies 500,000 pairs of combat boots a year.

(5)The general public often compares it to American combat boots, which is wrong. In the United States and other developed countries, professional soldiers also buy and wear them, and in the case of American combat boots, they cost more than 70,000 won. Two pairs of 100 people are free of charge. Anyway, the combat shoes made by the ocean industry are clearly different, and as a designated exhibition mobilization company, it has the ability to supply the best combat shoes stably during wartime and peacetime since its establishment. Deter

(6)In this regard, 61 President Park Geun-kyu said, “The technology know-how as the nation’s largest military shoe producer can win the competition with all domestic shoe manufacturers. If the products currently being branded are safely established in niche markets, the awareness of combat shoes will increase.”Along with Baltraxtar products, you will receive a two-month wear test evaluation. This product, made with its own technology, has the characteristic of reinforcing the six-stage cushion, including the insertion of a full window with anti-bacterial odor function, further enhancing the sense of fit.First of all, the price of combat shoes as of 2007 is 42,582 won per pair, which is very low compared to 70,000 won or more in commercial new shoes and 70,000 won to 100,000 won or more in U.S. combat shoes.

(7)Improved floor window patterns, reinforced the background and anti-slip, while greatly reducing wear. Although some netizens are raising the U.S. military’s Gore-Tex combat shoes compared to Korean combat shoes, the majority of combat shoe manufacturers believe that this is the source of ignorance.

(8)Waiting for the latest combat boots wear test

(9)In order to satisfy the needs of the new generation of soldiers, a Korean-style combat shoes development project is being promoted through the Ministry of National Defense service.

(10)The new combat shoes, which have become easier to take and take, will be distributed to the entire army from 2009 if they pass additional tests.First of all, the reason is that it is expensive and is not suitable for four seasons as a concept of cold weather.

(11)The Korea Shoes Institute made adhesive combat boots through Trextar and tested them on field units for a year from October 2006, and found additional supplements such as increased fatigue, sliding of floor windows, and moisture due to lack of sweat.

(12)Currently, executives, including Yang Sam-ju, 49, have been wearing these new combat shoes instead of personal shoes for a long time, and they can develop new materials, but they have to go through various processes before they can be distributed to the military.

(13)Product development → deliberation on military adoption → preparation of specifications → production → military wear test → military adoption and supplementary deliberation → military supply confirmation → production → distribution, etc., and it takes at least 3 to 5 years.

(14)Manager Yang said, “We wear them to show that they are superior to any other military supplier because they are our combat boots,” adding, “We’ve tried all the other nine military suppliers’ combat shoes, and we’re planning to wear them in the future.”Meanwhile, the development of combat shoes is not as easy or simple as it seems.

(15)The Ministry of National Defense plans to conduct a re-wearing test for two months between June and July for products that complement these problems.

(16)In the meantime, the ocean industry has been developing new combat shoes since 2007, and the latest materials with optimal conditions are being developed based on the function of sealed combat shoes and the results of the first unit test, which is a difficult procedure to apply to the military.

(17)We can’t meet the needs of the new generation of soldiers immediately because we have to go through it.

It’s this kind of company.

What about the U.S. military?

httpsgetfilefmkoreacomgetfilephpcode=73c8d3778957b6ab509cad5bc64702d6file=https3A2F2Fwwwdogdripnet2Fdvs2Fd2F232F032F062Fba0a7010737d213d4616ed9540d8c717webp

So it doesn’t matter which brand you use as long as you supply it according to the regulations.

Please shoot him.

Why don’t you get free transportation when you receive money from the country?